This article is intended to be a general overview of the steps to compliance with the DOE standards and testing for pumps the complete DOE rules provide greater detail.

With members of HI and others working closely with the DOE to develop the new regulations, the test procedures closely follow the HI’s existing test methods contained in HI 40.6-2014, Methods for Rotodynamic Pump Efficiency Testing. However, there are some exceptions and additional requirements put forth by the DOE to ensure repeatable and reproducible test results and to provide measurement methods and Water Treatment Equipments specifications for the entire scope of pumps under the rule.

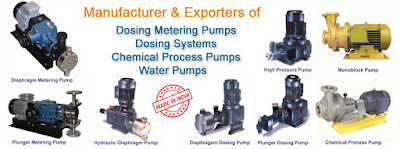

|

| Water Treatment Equipments Manufacturer |

1. What Will Be Tested?

The first step is to identify the parameters for each pump that falls under the rule. The standard targets five classes of rotodynamic pumps designated for use in pumping clean water in commercial metering pump manufacturers india, industrial dosing pump manufacturer india, agricultural and municipal applications:

Metering Pump Manufacturers India

Dosing Pump Manufacture India

The standards apply only to pumps with a best efficiency point (BEP) pump power input between 1 and 200 horsepower (hp); BEP rate of flow of 25 gallons per minute (gpm) or greater; BEP head of 459 feet or less; temperature between 14 and 248 F; and nominal speeds of 1,800 and 3,600 revolutions per minute (rpm). Pumps that are not within these parameters are not included in the standard. Pumps that are currently in use are not affected by the new regulations.

The final DOE ruling includes detailed definitions and examples of each pump type (single-stage, multistage, etc.), along with a list of pumps that are excluded from the ruling, such as circulators and pool pumps. The ruling also defines the meaning of the terms used in the test procedures, such as what constitutes a basic model or a driver or control.

Basic model encompasses all of the units of a given class of pump manufactured by one manufacturer, having the same primary energy source and essentially identical electrical, physical and functional (or hydraulic) characteristics that affect energy consumption, energy efficiency, water consumption or Chemical Dosing System.

That definition, however, does not cover all pump models, so the DOE has included a list of exceptions and further guidance for testing to eliminate ambiguity. For instance, basic model submersible turbine (ST) pumps are rated based on a nine-stage standard configuration, unless the basic model is not available with nine stages. If the basic model ST pump is only available with fewer than the required number of stages, the DOE rule states that the pump that should be tested is the one with the maximum number of stages with which the basic model is distributed in commerce in the U.S. If the pump is only available with greater than the required number of stages, the rule states that the pump with the lowest number of stages with which the basic model is distributed in commerce in the U.S. is what should be tested, and so on.

2. What Are the Metrics?

As noted above, the DOE has established a new metric called the Pump Energy Index (PEI) to rate the energy performance of pumps. Beginning Jan. 27, 2020, all pumps distributed in commerce in the U.S. must have a PEI less than or equal to 1.00. The PEI is a ratio of the representative performance of the pump being rated over the representative performance of a pump that would minimally comply with any prospective DOE energy conservation standard for that pump type.

Minimally compliant pump efficiency is determined by a calculation that includes specific speed, the BEP flow in gpm and a constant (C) that varies by pump type. This determines the Pump Energy Rating (PER), the weighted average of input power to the motor at defined duty points, and is the standard basis for all PEI ratings. The DOE’s rules on testing outline the steps to calculate PER in greater detail.

The ruling requires testing methods for both constant load and variable load equipment classes. A metric of pump energy index constant load (PEICL) applies to pumps sold without variable speed controls; pump energy index variable load (PEIVL) applies to pumps sold with variable speed controls. Both PEICL and PEIVL describe the weighted average performance of the rated pump at specific load points, normalized with respect to the performance of a minimally compliant pump without controls.

|

| Metering Dosing Pump Manufacturers in India |

3. What Is Required During Testing?

In setting up the actual testing procedures, the DOE follows HI 40.6 guidelines for permissible amplitude of fluctuation and the maximum permissible measurement device uncertainty. In addition, the DOE requires that at least two unique measurements be recorded more than five seconds apart and their mean computed. The DOE also requires that the two unique measurements are not farther away from the mean than the tolerance specified in the permissible amplitude of fluctuation table. Any damping devices are only permitted to integrate up to the data-collection interval.

Finalizing Procedures :

Although industry leaders have been supportive of efforts to reduce energy consumption and have acknowledged the need for regulatory standards to achieve the DOE’s ambitious energy goals, navigating the steps to certification will be an ongoing process. While there is still some unfinished work by the DOE, such as determining the reporting format, the new ruling puts pump manufacturers on a clear path to improving energy efficiency.

Focus Engineerrs Services :

No comments:

Post a Comment